Spray painting on the surface of materials can prevent rust and damage, and enhance the waterproofness, marking and aesthetics of the product. However, due to the long-term influence of temperature, humidity, air and other factors, the paint peels off, which affects the performance and appearance of the product and requires re-spraying. Paint removal is an important pre-treatment process before spraying.

Advantages of laser paint removal

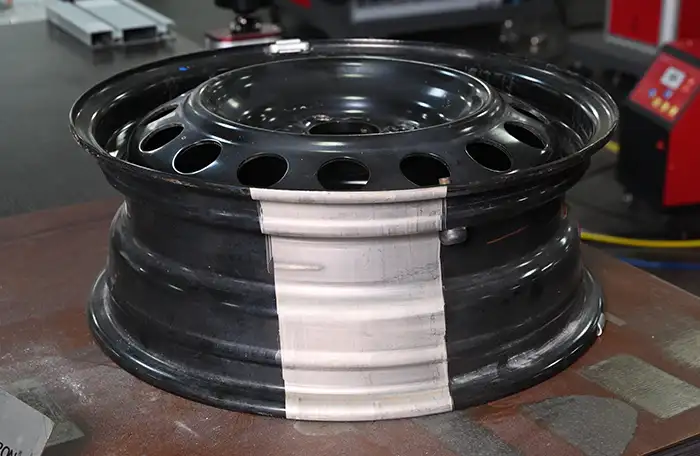

Laser paint removal is the clear choice over traditional solvent paint removal, mechanical paint removal, sandblasting paint removal, and other processing methods. The laser paint removal machine can select the processing range to reduce damage to the underlying substrate, without the use of chemicals, and is environmentally friendly and pollution-free. The laser beam is projected onto the surface of the product to be processed and is absorbed by the pigment molecules in the paint, causing the paint to decompose and fall off, and the cleaning and paint removal is completed.

The laser cleaning machine has strong functions and wide material applicability. It can complete the paint removal process on metal materials and non-metal materials. Our common cleaning materials include metal, wood, stone bricks, ceramic tiles, etc.

The laser beam can accurately reach the details and gaps of metal workpieces, effectively removing paint and residue from the surface without damaging the surface. On non-metallic materials, laser cleaning machines can skillfully remove layers of paint without affecting the grain and finish of items such as furniture, woodwork or antiques, reducing the risk of chipping or warping. In addition, laser cleaning machines are very effective in removing graffiti on walls, bridges and monuments. It can precisely control the cleaning range and intensity, and removes paint without scratching or damaging the structure of stone bricks or tile, thus extending the service life of the product.

Application range of laser paint remover

Mactron laser cleaning machines have various application types and can be used for rust removal, paint removal, oil stains and dirt removal, oxide layer removal, etc. Laser paint removal is a branch application in the field of laser cleaning. The processing field is very wide, including aerospace, automobile manufacturing, rail transit, shipbuilding, cultural relic restoration and other fields.

In addition to the paint removal cases shown in the above video, laser cleaning machines can also clean glass, ceramics and other new composite materials. For example, laser paint removal technology can effectively remove the paint layer on the surface of aircraft composite components and ensure the mechanical properties of the product; laser cleaning of the upper layer of paint on automobile parts can also ensure the integrity and functionality of the primer. In practical application cases, laser cleaning machines can also be equipped with automated robots to complete higher-demand paint removal tasks.

How to choose a laser paint removal machine?

As a high-tech paint removal method, the processing effect of laser paint removal will also be affected by many factors, including the type of paint layer (organic solvent paint, water-based paint, powder coating, etc.), the type of substrate (metal, wood, glass, etc.), surface shape (flat, curved, irregular, etc.), laser power and parameter settings, etc. If you have paint removal processing needs, you can contact us. We will take comprehensive considerations during the actual operation to ensure the paint removal effect, the performance of the substrate and the safety of the processing, etc., and customize the laser solution that suits you.